b. offer

Mounting plates and adjustable squares with complete equipment

c. why RAFAMET plates?

Choose us

EXPERIENCE

Construction of mounting plates has been designed basing on numerous examinations using the newest available engineer tools. Scrutiny analysis allowed to design plates which meet all requirements of the biggest Polish and European machine producers.

DURABILITY AND ACCURACY

Main characteristics of mounting plates produced by RAFAMET foundry include high durability, stiffness of the construction at maximum load and high accuracy of mechanical processing as well as advanced control of melting process using ITACA MeltDeck system.

QUALITY

The highest quality input materials are used in the process of production: pig iron and selected kinds of steel and cast iron scrap metals. All materials used in the production process are under laboratory verification. Plates provided to clients include a set of measurement cards and certificates.

rafamet foundry

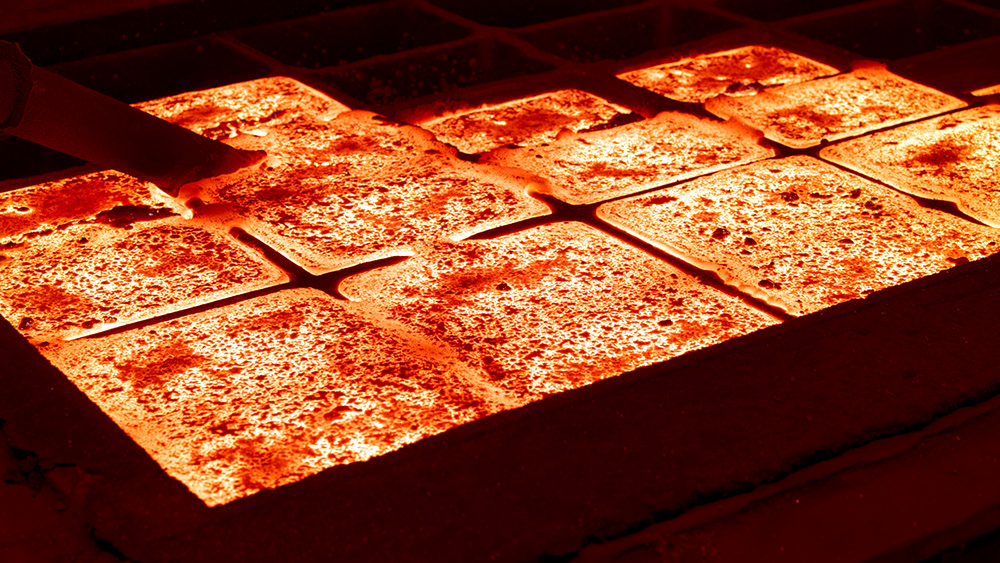

pouring molds

rafamet foundry

cast iron melting

rafamet foundry

pouring molds

rafamet foundry

pouring molds

rafamet foundry

pouring moldsm

rafamet foundry

pouring molds

rafamet foundry

pouring molds

1. contact us

RAFAMET Foundry Sp. z o.o.

ul. Staszica 1, 47-420 Kuźnia Raciborska, Poland

tel. +48 32/721 3351

e-mail:

www.odlewnia-rafamet.pl

2. company data